My Experiences with Hornindal Kveik After 4 Batches

Kveik has taken the homebrewer community by storm over the last few years. It was first introduced to the masses back in 2015-2016 by Lars Garshol and MilkTheFunk. Lars primarily (re)discovered this Norwegian family yeast and shared it with the world by sending samples to commercial yeast laboratories such as Imperial, Escarpment Labs and Omega among others.

I was let on to this secret by a coworker that told me Kveik is “now the only yeast I homebrew with.” Knowing that he liked New England IPAs as much as I did, I started to pick his brain. As it turns out, Kveik can essentially handle any environment you can throw at it, although it does have its preferences.

Don’t have good temperature control? Use Kveik.

Do you want one liquid package to last a handful of batches? Use Kveik.

Do you like slightly fruity yeast esters in your beers? Use Kveik!

Everything I read made me realize that I was stupid for not giving it a shot. I found Omega Hornindal online and had it shipped to me earlier this year. I ran four batches of beer through one single smack-pack of Hornindal, and I took a lot of notes. Hopefully these help someone else considering Kveik for their next batch.

Underpitching

No matter where you read about pitching Kveik in your homebrew, you’ll always see half the people saying to underpitch the amount of cells and others saying that you definitely need to make a starter in order to properly attenuate the beer and prevent stalling or off flavors.

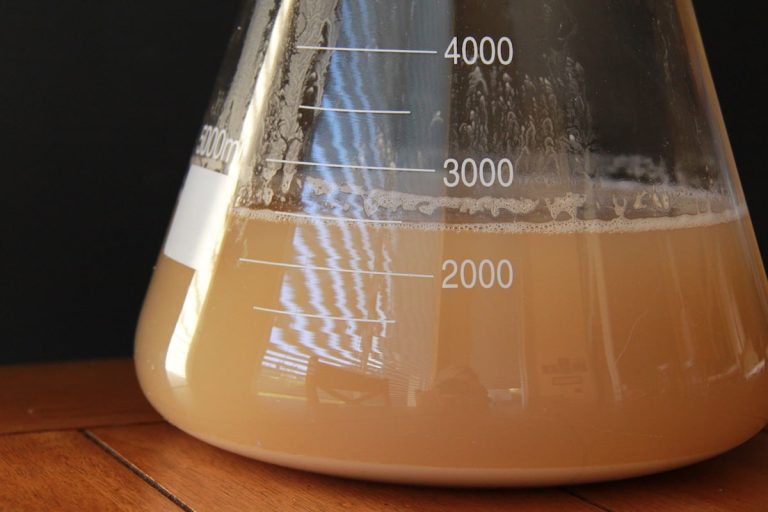

I’m here to tell you that I dropped my liquid pack into a sanitized mason jar and threw it in my fridge. On brew day, I took the jar out of the fridge and sat it on the counter while my wort heated up and boiled. When it came time to pitch the yeast, I only pitched about a tablespoon or so of the semi-cold slurry into my 6.5 gallon glass carboy fermenter filled with ~5.5 gallons of 90° F wort and it took off like a rocket within a few hours.

I used this same under pitching method (approximately 1-1.5 tablespoons of slurry) on the following beers:

- A 1.078 original gravity Black IPA

- A 1.070 original gravity Pliny the Elder clone

- A 1.058 original gravity Oatmeal Stout

- A 1.061 original gravity All Together IPA

All batches reached final gravity within 3 days, but most were left to condition a bit in the glass carboy for another 4 days or so.

Flavor Profiles

The Black IPA was maybe the best batch I’ve ever done. It was equal parts smooth, chocolaty, hoppy and tropical all at once. It was a fantastic mix of flavors that I hope I can duplicate the next time I brew it.

It did have a bit of a rum taste during bottling and for about 2-3 weeks after bottle conditioning. That is a flavor that MilkTheFunk mentions as a flavor to be expected with Hornindal. The tropical notes have subsided a bit while in the bottle, but are still there, and I attribute those to the hot start I provided the yeast since I pitched at around 90° F.

There was a bit of a mistake when pitching the yeast into the Pliny clone. My thermometer read 90° F, so I stopped my immersion chiller, siphoned the wort into my fermenter and pitched the yeast. I found out shortly there-after that my wort was actually about 110° F and my thermometer must have been a little too close to my IC. I should have stirred the wort to ensure the full 5 gallons were the same temp, but I didn’t.

Luckily, I didn’t notice any off flavors at all. The Pliny clone was super, super hoppy as expected, but didn’t have any odd flavors from the hot start or the under pitching. I ended up bottling this one and have not noticed any adverse effects from starting the fermentation at such a high temperature.

The All Together NEIPA was a bit tart or “farmhouse-style”, which I’ve found twice with this particular strain of Kveik. This farmhouse-style flavor is not something I was a fan of at first, but it wasn’t as overpowering as some commercial farmhouse ales I’ve had in the past. It was subtle, but I could definitely tell it was there.

Adding Heat

With all of these batches, I used a heating pad to help keep the fermentation temperatures as high as they would go since Kveik love to ferment at high temps. After pitching at 90° F, I would place the full carboy on top of my heating pad. Unfortunately the pad I have doesn’t have variable temperature settings – it’s either “ON” or “OFF” – but that didn’t matter much with 5 gallons of wort. It had no problems keeping the temperature in the 80’s. After terminal gravity was reached (or close to it), I turned off the heating pad and let the beer come to room temperature for the rest of it’s stay in the fermentation vessel.

Now, this is not something you’d want to do with any type of yeast other than Kveik. Normally, to keep off flavors to a minimum, all other yeasts should be pitched at MUCH lower temperatures. The only type of beer you’d might be able to get away with higher temps like this would be with darker beers.

Reusing Yeast

I recently wrote an article about the ways I’ve stretched the use of a single yeast packet to save money. One of the ways was to reuse the trub from the All Together batch. I did this on my 1.058 (OG) Oatmeal Stout and had no problems with it at all.

I took about 1 full pint of trub from the NEIPA and threw it into a sanitized mason jar after I was done racking it into my keg. The jar sat in my fridge for about 3 days until I brewed the Oatmeal Stout, and after pitching the full jar into the carboy, the fermentation took off vigorously within two hours. This particular batch had no problems with attenuation, off flavors or fermentation time. It was a very clean tasting brew that didn’t have the tropical or rum-like notes I was expecting.

Use Nutrients

Maybe I should do a Brulosophy-style test on this one day, but with these batches I didn’t take the chance. I added between 3-6 teaspoons of LD Carlson yeast nutrient to each of my batches with about 10 minutes left in the boil. Kveik is well known to have higher-than-normal nutrient requirements, so I played this one safe and just followed the directions.